Cases

- All

- Engineering

- Productdesign

- Simulation

- Heavy Lifting

- Reverse Engineering

- 3D Scanning

- Consulting

- Prototyping

-

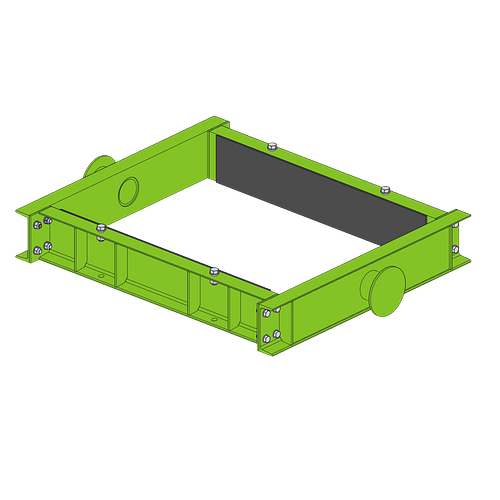

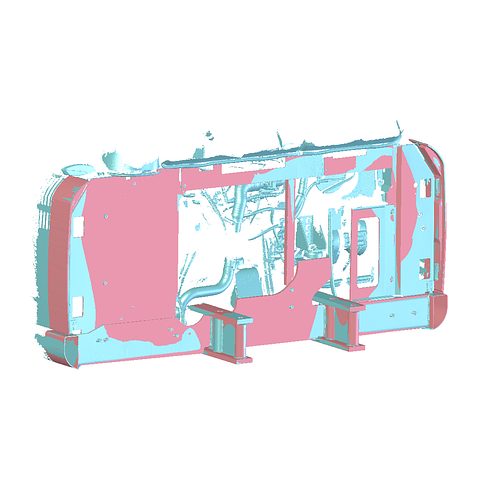

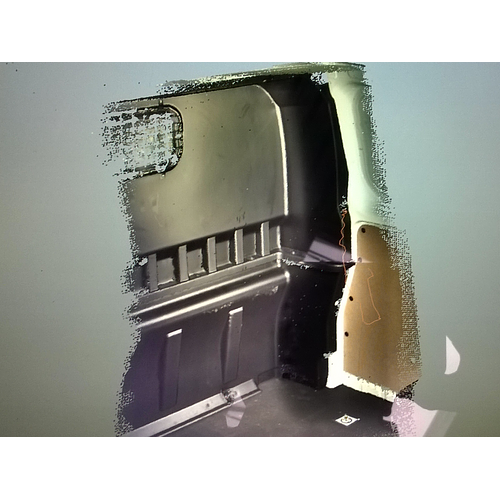

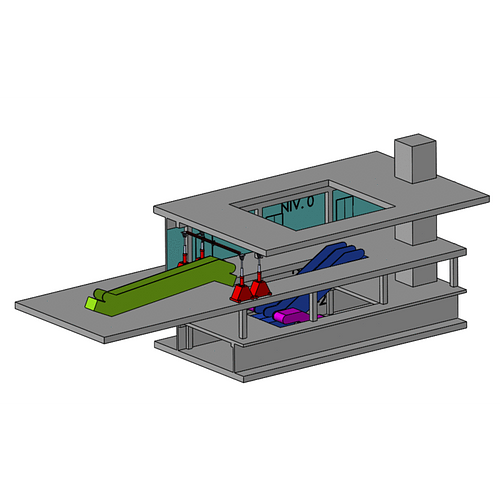

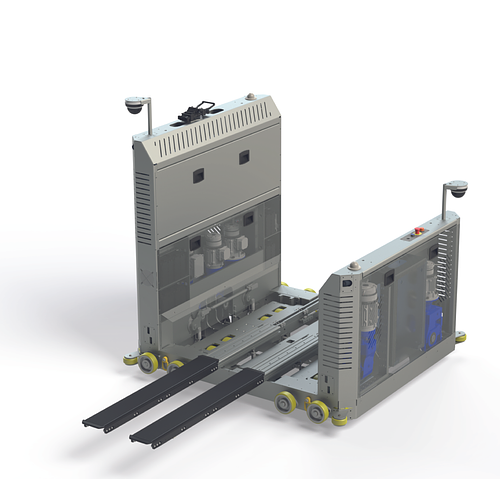

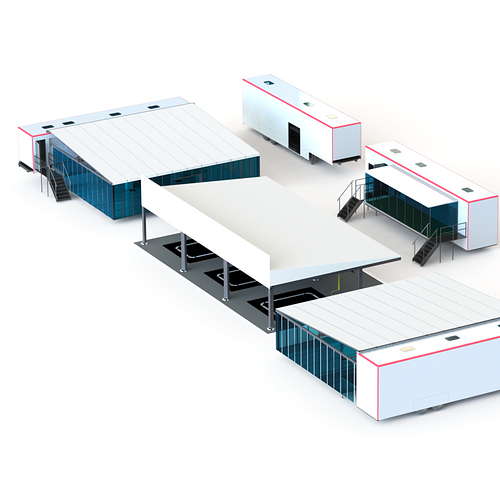

SEC-construction - Toyota City

Read moreSec-Construction is gespecialiseerd in het bouwen van Racing Service Semi-Trailers, motorhomes, paardenvrachtwagens, campers en speciale voertuigen. Bij aanvang van de 'World Rally Championship' legde Toyota hen de vraag voor een nieuw rallydorp voor. Door...